When catastrophic hail and windstorms hit Fort Carson and surrounding areas, over 3.2 megawatts (MW) of distributed solar photovoltaic (PV) systems were severely damaged and production capability for the systems completely lost. The damage prevented the solar PV systems from being able to deliver clean, reliable solar power and minimized the utility cost savings the post has realized for over five years. With a limited budget for existing infrastructure improvements, we were tasked with finding a way to restore system power production without demolishing the damaged systems and replacing with new equipment.

A PV module impaled on an array in Fort Carson after severe wind and hail events.

A PV module impaled on an array in Fort Carson after severe wind and hail events.

Finding the Right Fit

The region is used to wind and hail events, but none as severe as the combination of the three storms that took out most of its distributed PV system infrastructure. When the events occurred, the client was left with three unique challenges:

- How to repair the infrastructure and return production to 100%

- Confirming new components complied with Buy American Act requirements

- Completing the project amidst a global pandemic

Completely replacing the damaged systems was not an option. To get started on a solution, we conducted detailed site surveys, facilitated workshops, and presented alternative design and construction solutions. The scope of work included repairs of eleven PV systems, which provided another challenge. Each PV system had modules with different dimensions depending on the manufacturer, so we were tasked with trying to piece them back in with compatible racking systems across each of the sites.

Several modules were damaged by hail on one of many carport arrays on the base.

Several modules were damaged by hail on one of many carport arrays on the base.

The critical infrastructure includes power generating systems and treatment plants for approximately 65,000 users.

The critical infrastructure includes power generating systems and treatment plants for approximately 65,000 users.

Keeping Production Going

Using what was available to us, we pieced systems together to deliver 100% of the baseline system production capacity. We completely restored what was lost in the damage, reusing a majority of what was onsite and installing new system components, such as modules and inverters.

We reused viable system components from two of the sites that were then distributed to the other sites to infill voids left by damaged components. This approach allowed us to reconstruct complete and functional arrays with similar components.

Using what was available to us, we pieced systems together to deliver 100% of the baseline system production capacity. We completely restored what was lost in the damage, reusing a majority of what was onsite and installing new system components, such as modules and inverters.”

Christian Marsh-Frydenlund

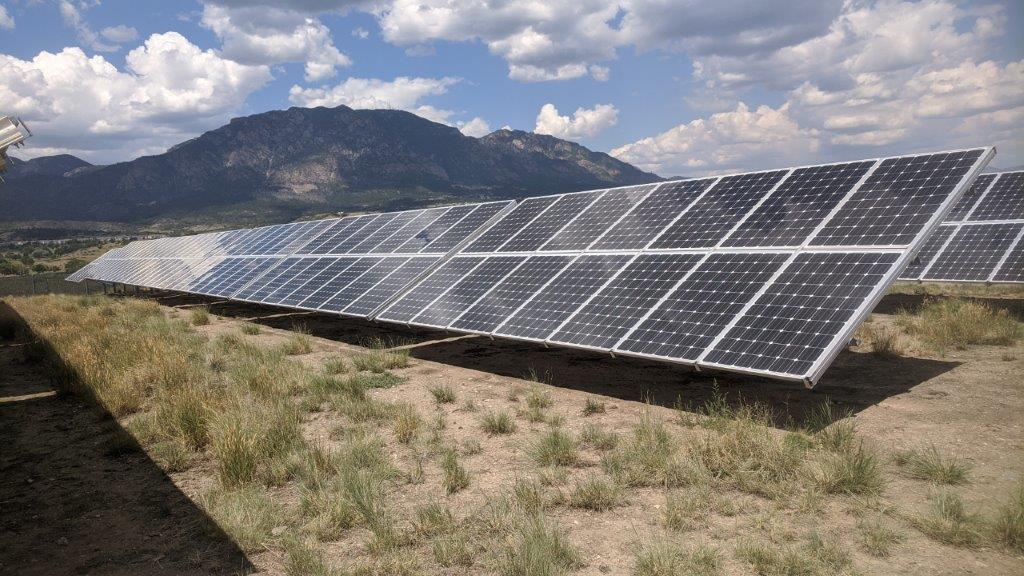

Repaired arrays were brought back to 100% capacity without having to replace the entire infrastructure.

Repaired arrays were brought back to 100% capacity without having to replace the entire infrastructure.

Working with What You Have

The biggest takeaway from this project was that it's important to work with what you have regardless of budget constraints. If we hadn’t, we wouldn't have been able to restore the power production of the damaged systems to pre-damage capacity without significant additional capital. Without creatively reusing what was left of the PV systems and the budget available for repairs, we would have been limited to decreased production and wasted materials that could not be recycled.

Another lesson that resonated with us was finding a solution that would work for many years to come. Having the right team of design-builders to look for innovative and unconventional engineering and construction solutions was the only way this project was going to turn out the way it did. We applied the process we always do. We went in and tested, evaluated, and surveyed to determine what was broken. Then together with the client, we came up with a solution that was successful.